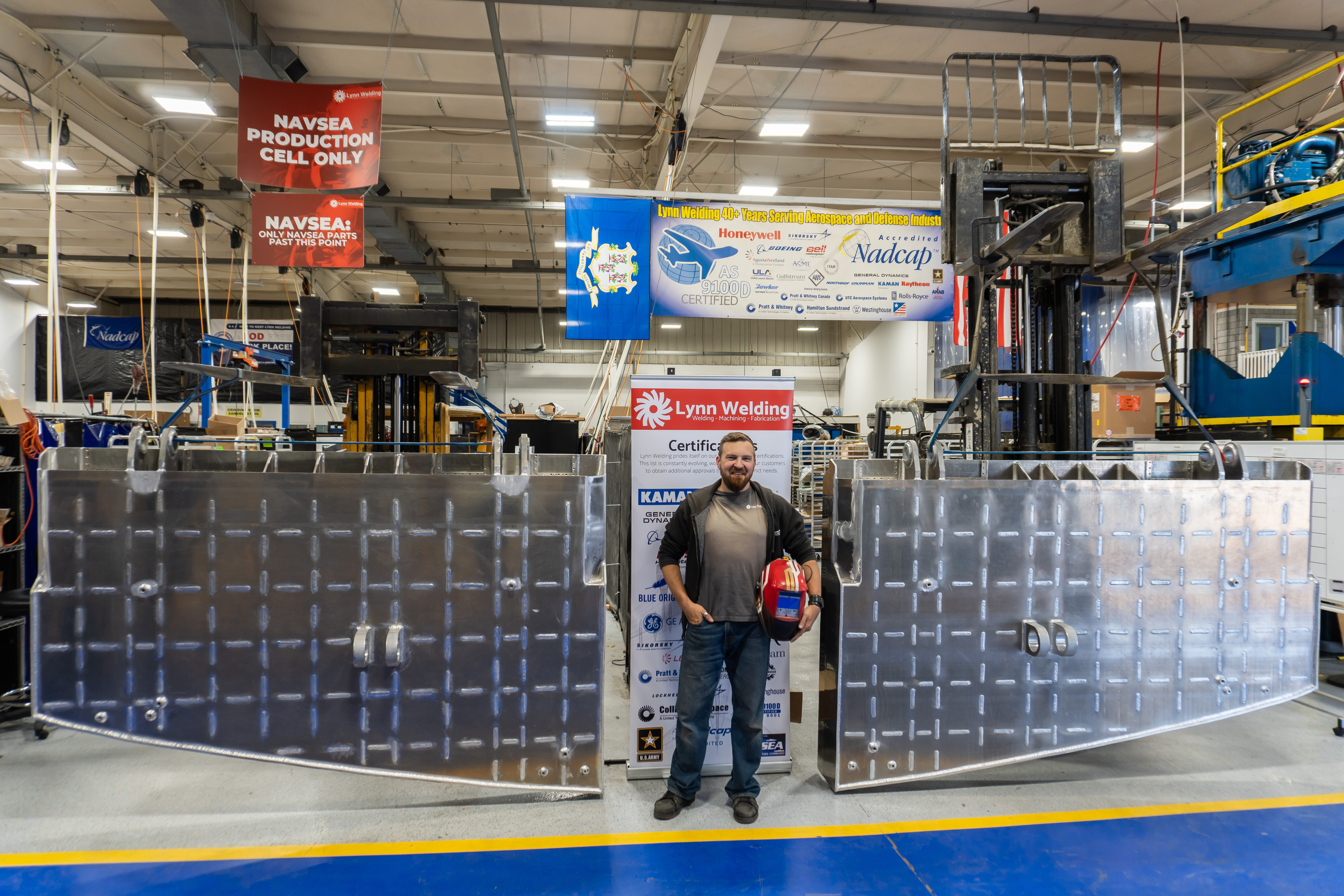

At Lynn Welding, we take immense pride in the expertise and dedication of our skilled craftsmen, and today, we’d like to spotlight one of our talented welders, Gregg M. Gregg recently completed a challenging and impressive trim tab project, showcasing the skill and precision that defines our work.

These trim tabs, each weighing over 1,000 lbs, are vital components constructed from marine-grade aluminum. Trim tabs operate under extreme pressure from hydrostatic drag and are designed to enhance a ship’s performance by adjusting its running angle. This makes them crucial for maintaining a vessel’s efficiency and stability in some of the world’s toughest sea conditions. For this reason, Lynn Welding was selected for the job due to our unmatched expertise in welding aluminum alloys—a material that requires specialized handling to ensure strength and durability.

The heart of this project lies in Gregg’s mastery of fusion welding. Hundreds of pounds of specialty aluminum weld wire were deposited into these weldments to guarantee they withstand the incredible forces they’ll face at sea. Internally, the trim tabs are reinforced by stiffener plates arranged in a crisscross pattern, adding strength without excessive weight. This design requires over 500 weld joints on each trim tab—each of which needs to be meticulously executed to avoid warping or other issues caused by improper welding sequences.

Gregg’s expertise and attention to detail played a critical role in ensuring the welds were applied in the correct order, preserving the structural integrity of the parts. His careful approach to each weld joint helped prevent potential deformations that could affect the trim tab's performance. Following the welding process, the trim tabs will undergo a stringent pressure test to confirm they are leak-tight and fully capable of withstanding their future marine environment.

What makes this project even more challenging is the need for precise control over the heat-affected zones (HAZ) to ensure that the base material retains its tensile strength. This is particularly important in aluminum welding, where excessive heat can compromise the material’s integrity. By applying his deep knowledge of aluminum welding techniques, Gregg ensured that the welds remained robust while the material itself maintained its required strength.

Lynn Welding’s extensive experience in handling complex aluminum weldments made us the ideal partner for this project. The completion of these trim tabs is a testament to our commitment to delivering high-quality welding solutions for even the most demanding applications. Gregg M.’s work is a prime example of the dedication, skill, and attention to detail that Lynn Welding brings to every project.

We are proud to have Gregg on our team and celebrate his contribution to this successful endeavor. His craftsmanship not only reinforces the strength of these critical components but also highlights Lynn Welding’s position as a leader in the welding industry.

COMMENTS